BREAKING NEWS FOR DHOLERA

INOXAP joins forces with ReNew to power India’s first solar PV cell facility at Dholera

29th Nov 2024 Source by https://www.manufacturingtodayindia.com/The partnership also incorporates gas management for supply, distribution, and onsite handling, advancing ReNew’s renewable goals.

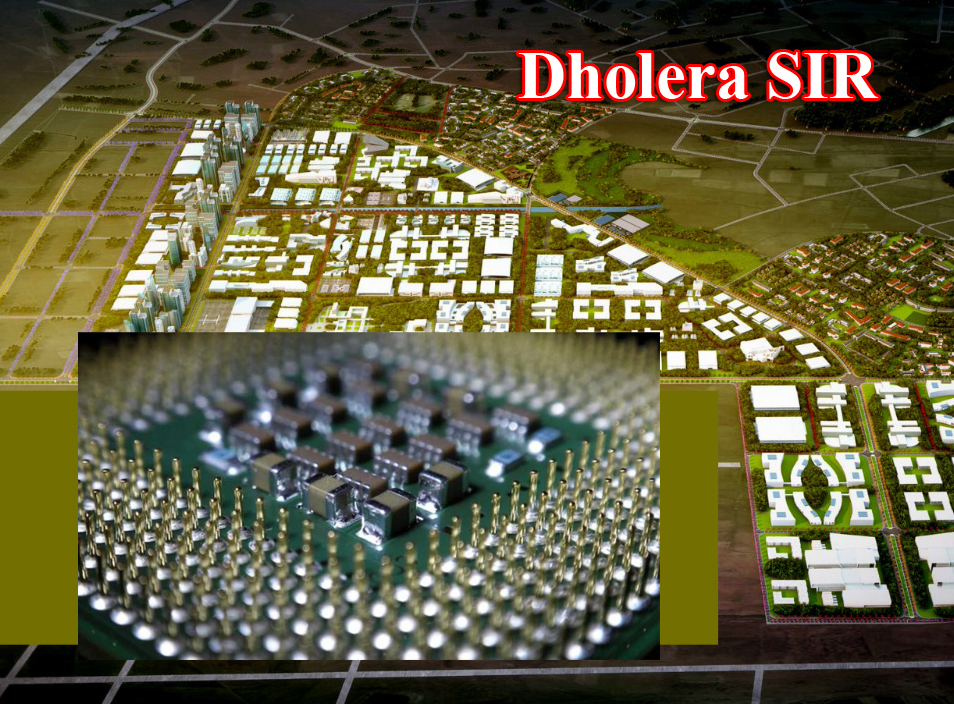

INOX Air Products (INOXAP) has started providing electronic and speciality gas supplies to ReNew’s first solar PV cell manufacturing facility in Dholera, Gujarat. Under a long-term agreement, INOXAP will supply essential gases like Nitrous Oxide, Ammonia, and Silane using a robust supply chain featuring state-of-the-art ISO containers and tube trailers. This ensures that ReNew has a steady supply that meets its operating and high-quality needs.

The partnership also incorporates a comprehensive gas management solution covering supply, distribution, and onsite handling, further supporting ReNew’s renewable energy goals. INOXAP’s ISO containers and specialised trailers meet stringent safety standards, reducing emissions while enhancing delivery efficiency. These reusable containers align with both companies’ sustainability goals, enabling eco-friendly PV cell production.

Siddharth Jain, Managing Director of INOXAP, emphasised their commitment to empowering the renewable energy sector by providing innovative, high-purity gas solutions to support India’s green energy transition. Kailash Vaswani, CFO of ReNew, highlighted how the collaboration sets a benchmark for efficient and sustainable solar PV cell production, strengthening India’s energy independence.

This partnership underlines the importance of innovative logistics in driving reliable clean energy production, contributing to India’s sustainability objectives.

Lam Research to support Dholera’s semiconductor plant with new office

29th Nov 2024 Source by https://www.manufacturingtodayindia.com/The technological competence of the Lam Research is evident in the extensive adoption of Semiverse.

In Dholera, Gujarat, Tata Electronics plans to establish the nation’s first semiconductor production plant. Powerchip Semiconductor Manufacturing Corporation of Taiwan is a partner in this project. The regional division of the American wafer manufacturing equipment provider, Lam Research India, intends to establish an office in Dholera in recognition of the significance of local support for this ambitious endeavor.

The corporate vice president and general manager of Lam Research India, Rangesh Raghavan, claims that this calculated action would guarantee on-site client care, which is essential for handling the intricate requirements of semiconductor manufacture. Front-end wafer processing, a crucial step in creating vital semiconductor components including transistors and interconnects, is supported by Lam Research Corporation technology.

The technological competence of the Lam Research is evident in the extensive adoption of its state-of-the-art virtual fabrication modeling system, Semiverse, for modeling fabrication processes. The rising need for electronics, artificial intelligence, and smart gadgets is expected to propel India’s semiconductor industry, which is now valued at USD 23.2 billion, to USD 80.3 billion by 2028. The Production Linked Incentive (PLI) Scheme is one of the strong financial incentives provided by the Indian government’s 2020 Semiconductor Policy to lessen reliance on imports and encourage self-reliance.

Under the Leadership of Chief Minister, Gujarat’s Tech Landscape Achieves a New Milestone

14th Nov 2024 Source by https://cmogujarat.gov.in/MoU Signed Between Gujarat’s Science and Technology Department and Global Industry Leader Jabil.

Jabil to Set Up an Electronics Manufacturing Services (EMS) Unit with ₹1,000 Crore Investment in Dholera Special Investment Region (DSIR)

MoU to Propel Prime Minister Shri Narendra Modi’s "Make in India" Initiative

Jabil’s New Unit Expected to Commence by 2027, Creating Around 5,000 Employment Opportunities

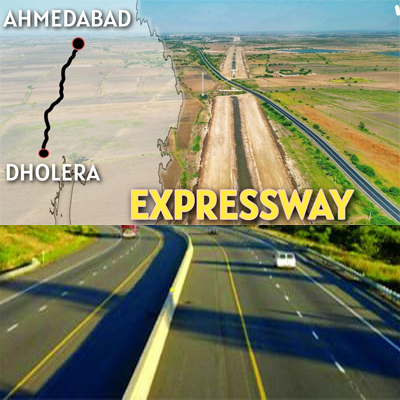

Ahmedabad: The construction of the 109-kilometer expressway linking Ahmedabad with the smart city of Dholera is advancing swiftly, with approximately 80% of the work complete. Expected to become operational by early 2025, the, built at a cost of Rs. 4,373 crores, will reduce travel time between the two cities to just 40 to 45 minutes.

With the visionary guidance of Prime Minister Shri Narendra Modi, India has emerged as a global leader in technological transformation, positioning itself as a hub for digital innovation. The India Semiconductor Mission, India AI Mission, and National Quantum Mission are set to revolutionize the electronics manufacturing sector, alongside advancements in AI, IoT, and 5G technology.

Nearly 80% of Ahmedabad – Dholera expressway work complete; expected to open in 2025

7th Nov 2024 Source by https://deshgujarat.com/Ahmedabad: The construction of the 109-kilometer expressway linking Ahmedabad with the smart city of Dholera is advancing swiftly, with approximately 80% of the work complete. Expected to become operational by early 2025, the Ahmedabad-Dholera Expressway, built at a cost of Rs. 4,373 crores, will reduce travel time between the two cities to just 40 to 45 minutes.

The expressway will connect the Sardar Patel Ring Road in Ahmedabad with India’s first Greenfield Smart City. Many YouTube vloggers have visited the site to track its progress. Recently, RS Live shared updates on the construction phases.

Beginning from Ahmedabad, construction work on the diamond interchange at the SP Ring Road is nearly complete, with one side already open for traffic, while the other side remains closed.